Chocolate

Filter

Sort by:

Description

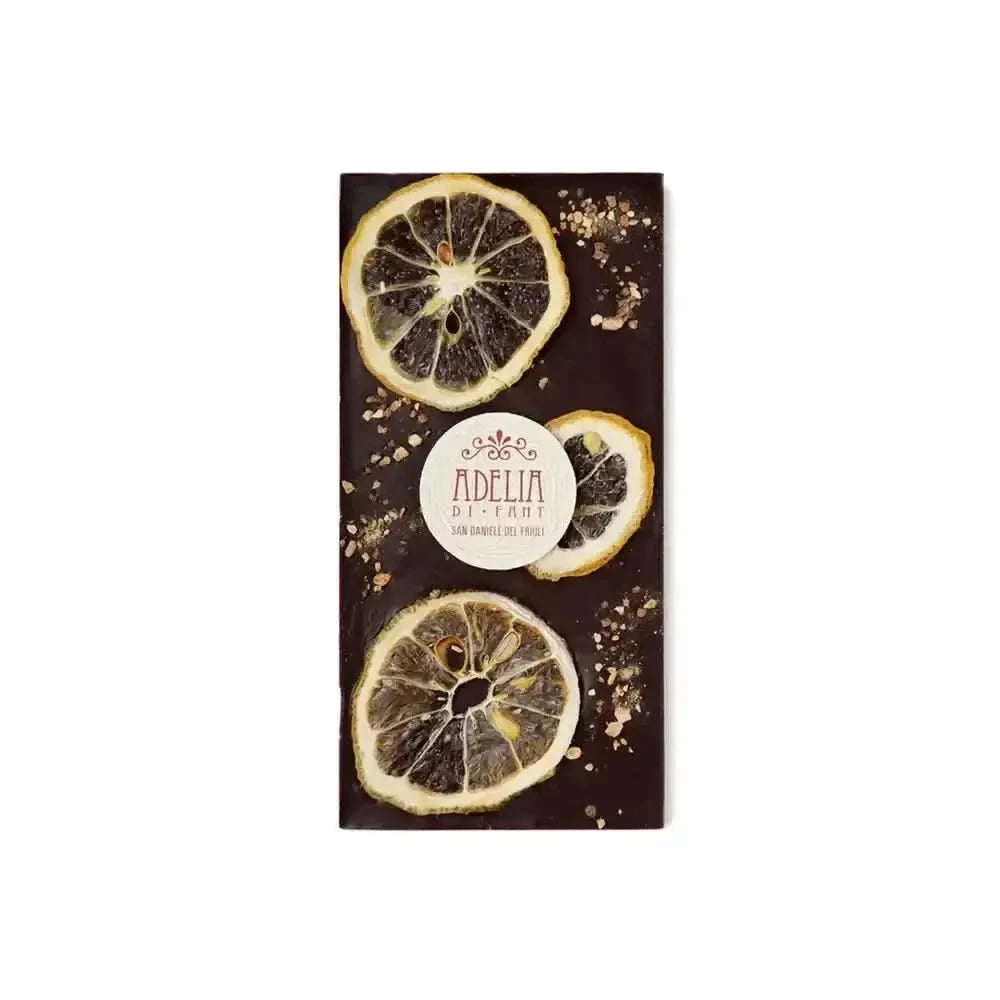

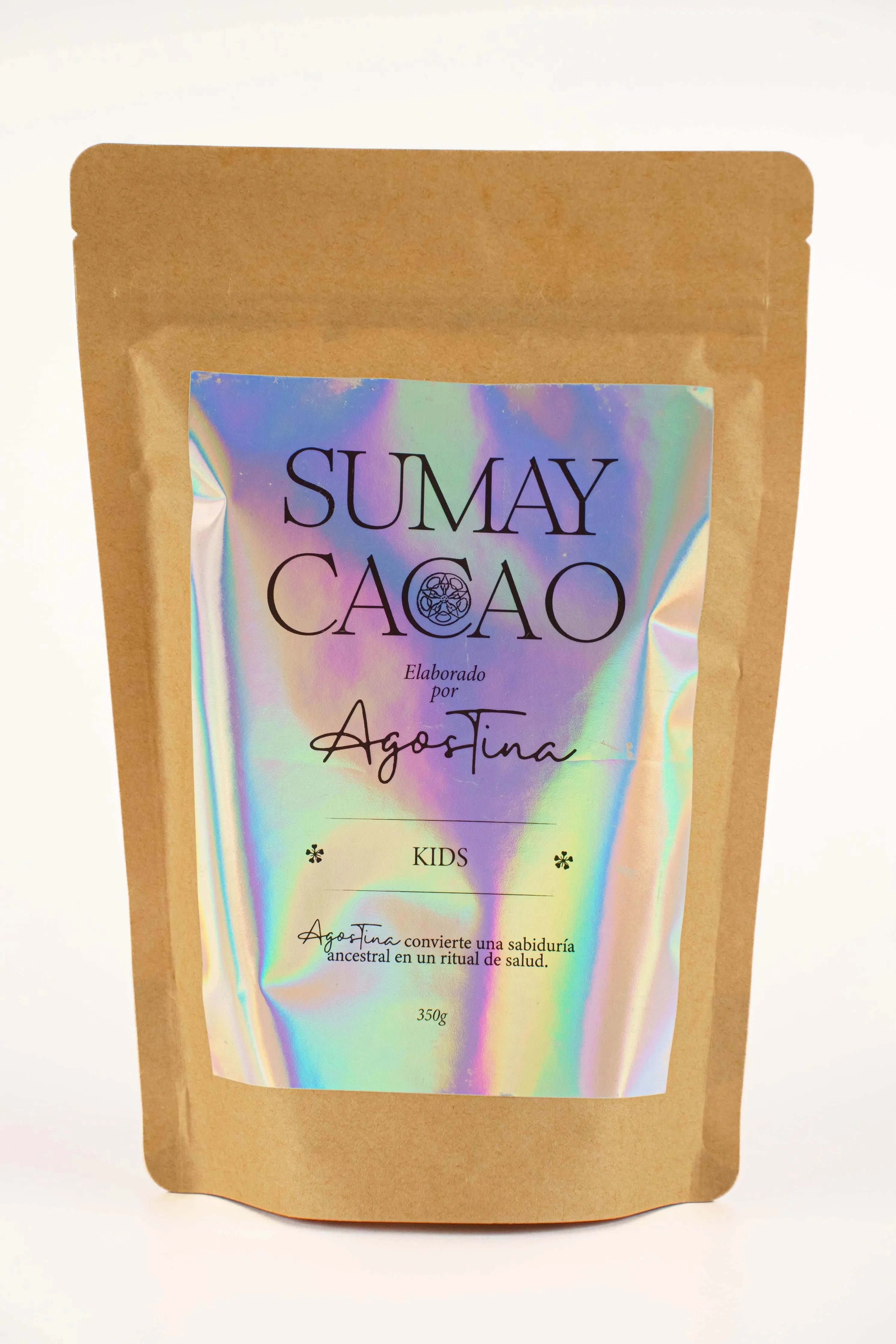

Chocolate Collection: Artisanal Cacao Preparations

Chocolate derives from the meticulously processed seeds of Theobroma cacao, a tropical tree native to the Amazon Basin. The production begins with harvested cacao pods containing 20-50 beans surrounded by white pulp. These beans undergo fermentation, developing precursor compounds essential for chocolate's complex flavor profile. Following fermentation, beans are dried, cleaned, and roasted to further develop flavor through Maillard reactions between amino acids and reducing sugars.

Chemical Composition and Technical Classification

Chocolate's primary components include cocoa solids, cocoa butter, sugar, and sometimes milk solids. Cocoa solids contribute flavor compounds including theobromine, caffeine, and various polyphenols. Cocoa butter, composed primarily of oleic, stearic, and palmitic fatty acids, provides chocolate's unique melting properties. Standard chocolate contains approximately 300-500 distinct flavor compounds, making it among the most chemically complex foods available.

Structural Properties and Quality Indicators

Premium chocolate exhibits five key quality markers: clean snap when broken, indicating proper crystalline structure; smooth mouthfeel without grittiness; complex flavor development with multiple distinguishable notes; controlled melting curve near body temperature; and characteristic sheen indicating proper tempering. Particle size reduction to approximately 20 microns significantly influences texture perception, with properly manufactured chocolate containing no detectable particles on the palate.

Types

Popular Chocolate Varieties and Technical Classifications

White Chocolate Composition and Technical Properties

White chocolate contains cocoa butter (min. 20%) without cocoa solids, creating its characteristic ivory appearance. Quality indicators include natural vanilla flavor compounds rather than vanillin, minimum 14% milk solids, and maximum 55% sweeteners. Premium white chocolate undergoes proper tempering to develop stable crystal formation, resulting in clean snap and silky mouthfeel. This variety demonstrates unique melting properties due to its fatty acid profile dominated by stearic and palmitic acids, creating sharp melting curves near body temperature.

Milk Chocolate Technical Parameters and Regional Variations

Milk chocolate combines cocoa solids (min. 10-12%), cocoa butter, milk components, and sweeteners. European standards require minimum 25% total cocoa content, while American standards permit 10%. Superior milk chocolate contains 30-40% cocoa with precisely controlled milk protein content affecting flavor development. The Maillard reaction between milk proteins and reducing sugars during manufacturing creates characteristic caramel notes. Swiss milk chocolate traditionally undergoes longer conching periods (60+ hours) developing distinctively smooth texture profiles.

Dark Chocolate Classification and Quality Factors

Dark chocolate contains cocoa solids (min. 35%) with varying concentrations determining intensity. Products with 70%+ cocoa content exhibit pronounced bitterness and reduced sweetness with higher theobromine concentrations. Specialty dark chocolates include single-origin varieties showcasing distinctive terroir characteristics from specific growing regions. Bean-to-bar producers often specify exact percentages, processing methods, and bean origins, creating distinctive flavor profiles based on genetics, growing conditions, and manufacturing techniques. Origin-specific products from Madagascar typically present red fruit acidity, while Venezuelan varieties exhibit nutty characteristics.

Specialized Chocolate Formulations

Couverture chocolate contains higher cocoa butter percentages (32-39%) optimized for confectionery applications requiring specific flow properties. Ruby chocolate, developed in 2017, utilizes specific cocoa bean varieties and processing methods to create distinctive pink coloration and berry flavor notes without additions. Compound coating formulations substitute alternative fats for cocoa butter, eliminating tempering requirements while sacrificing characteristic melting properties. Raw chocolate maintains processing temperatures below 42°C to preserve heat-sensitive compounds, though technically undergoes fermentation exceeding this temperature threshold.

Benefits

Chocolate Health Benefits and Physiological Effects

Bioactive Compounds and Functional Properties

Cocoa contains over 380 identified chemical compounds, with polyphenols comprising approximately 10% of cocoa's weight. Flavanols, particularly epicatechin and catechin, represent the predominant bioactive compounds responsible for chocolate's physiological effects. These compounds demonstrate antioxidant activity through free radical neutralization and metal chelation mechanisms. Research indicates that dark chocolate, minimally processed and containing 70%+ cocoa content, delivers the highest flavanol concentrations. Processing methods significantly impact bioactive content, with alkalization (Dutch processing) reducing flavanol content by 60-90%.

Cardiovascular System Effects and Mechanisms

Chocolate's flavanols demonstrate vascular benefits through nitric oxide modulation pathways. Regular consumption correlates with modest blood pressure reduction (2-3 mmHg systolic) through improved endothelial function. Studies indicate improved platelet function with decreased aggregation potential after dark chocolate consumption. The stearic acid content, despite being saturated, demonstrates neutral or beneficial effects on blood lipid profiles unlike other saturated fatty acids. Meta-analyses suggest moderate dark chocolate consumption may reduce cardiovascular disease risk by 37% compared to minimal consumption.

Neurological Functions and Cognitive Effects

Chocolate contains psychoactive compounds including theobromine, caffeine, anandamide, and phenylethylamine that influence brain function. The theobromine content (250-500mg/100g) provides mild stimulation while exhibiting longer half-life than caffeine. Flavanol compounds demonstrate neuroprotective effects with potential cognitive benefits, particularly in older adults with early memory decline. Specific flavanol metabolites cross the blood-brain barrier, potentially enhancing cerebral blood flow and neurogenesis. Regular consumption correlates with reduced risk of cognitive decline in longitudinal studies.

Mood Modulation and Psychological Effects

Chocolate consumption triggers multiple sensory and biochemical pathways influencing psychological state. The combination of sugar, fat, and flavor compounds stimulates dopamine and serotonin release, creating pleasure responses. Studies demonstrate stress hormone reduction with dark chocolate consumption through cortisol pathway modulation. The sensory experience, including aroma, mouthfeel, and flavor complexity, activates multiple reward pathways. These combined mechanisms likely explain chocolate's historical association with comfort and celebration across cultures.

Instructions

Chocolate Storage, Preparation and Usage Techniques

Optimal Storage Parameters for Maximum Quality Retention

Chocolate requires storage between 15-18°C (59-65°F) with relative humidity below 50% to maintain optimal quality. Temperatures exceeding 23°C (73°F) initiate cocoa butter softening, while fluctuating temperatures promote fat bloom development. Proper storage utilizes airtight packaging that blocks light, oxygen, moisture, and odors, as chocolate readily absorbs external aromas. Premium dark chocolate maintains optimal quality for 18-24 months when properly stored, while milk and white varieties typically maintain quality for 12-16 months due to potential milk fat rancidity.

Melting and Tempering Technical Parameters

Proper chocolate melting requires temperatures between 45-50°C (113-122°F) to completely liquefy cocoa butter while preventing compound degradation. Tempering dark chocolate requires cooling to 27-28°C (80-82°F), followed by crystallization at 31-32°C (88-90°F). White and milk chocolate require slightly lower tempering temperatures at 28-29°C (82-84°F). Properly tempered chocolate exhibits Form V crystal structure providing optimal snap, shine, and shelf stability. Seed tempering utilizing pre-tempered chocolate introduces proper crystal structures to initiate uniform crystallization throughout the mass.

Culinary Applications and Technical Considerations

Chocolate functionality in baking applications depends on fat content and particle size distribution. Ganache preparations require specific chocolate-to-cream ratios based on cocoa butter percentage and intended application. Chocolate and water preparations require precise emulsification techniques to prevent seizing. Chocolate pairings benefit from complementary flavor compounds, with specific wine varieties sharing terpene profiles with single-origin chocolates.

FAQs